Technical articles

Temperature efficiency values: Definitions and requirements

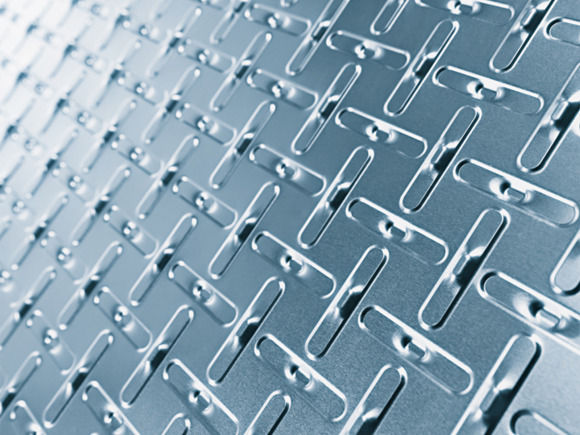

Condensation in the plate heat exchanger increases efficiency and pressure drop

Regulating output with bypass system

Consider the pressure difference

Freezing of condensate in the plate heat exchanger