Sorption rotary heat exchangers

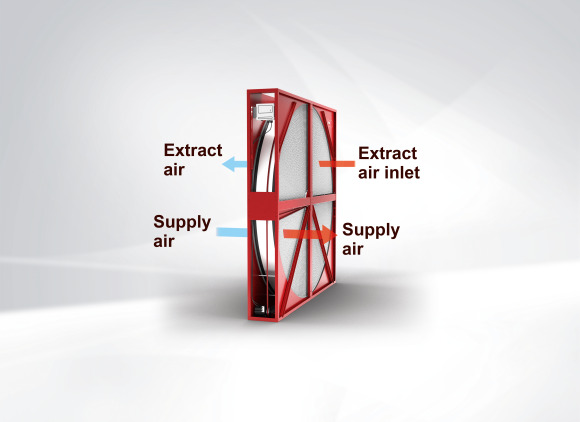

Air flow through rotary heat exchanger

Operation

Rotary heat exchangers transfer energy through a rotating storage mass, which is alternately heated by one air stream and cooled by the other. They can transfer both temperature and humidity between air streams.

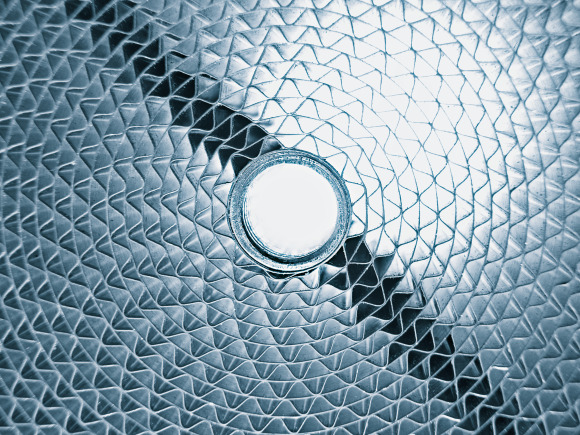

The storage mass consists of aluminium foil. A smooth and a corrugated foil are wound on top of each other to form a wheel of sinusoidal channels. Warm air and cold air flow through these alternately and thus transfer the heat between the two air streams.

Their storage mass is largely or even completely coated with a hydrophilic material. Therefore, they transfer humidity between the air streams all year round. The sorption coating guarantees maximum humidity transfer for all seasons. In summer operation, the supply air is not only precooled, but also significantly dehumidified at the same time. This in turn reduces the subsequent cooling demand. As a result, the output of the cooling units does not need to be as high and their dimensions can be reduced, thereby reducing both running and investment costs.

Sorption rotary heat exchanger designs

Muonio (HM1)

The aluminium foil used for the storage mass is completely coated with molecular sieve 3 Å. This makes Muonio exchangers a high-performance model. The sorption coating guarantees maximum humidity efficiency throughout the year.

In summer operation, the supply air is dried. The cooling requirement to be covered by a cooling unit is considerably reduced. This saves both investment costs and energy costs for cooling. In winter operation, humidity transfer improves the indoor climate.

SH1

Areas of application

The sorption coating ensures maximum humidity transfer all year round. This means that, in the summer, the cooling demand that has to be covered with cooling units is reduced. While in the winter, the indoor climate is improved significantly. As a result, the sorption rotary heat exchanger is ideal for use in ventilation systems with mechanical cooling.

Application limits

- Diameter: 500–4200 mm

- One-piece Ø500–2600 mm, segmented Ø950–4200 mm

- Air flow rate from approx. 200 to 150 000 m³/h

- Differential pressure between the air streams max. 1000 Pa

- Pressure drop for 1-piece wheels max. 300 Pa

- Pressure drop for segmented wheels max. 400 Pa

Year-round temperature and humidity control.